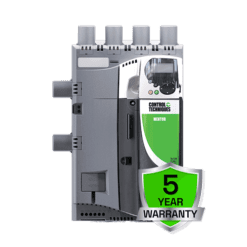

Pump Drive F600

Pump Drive F600

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

This product comes with 5-year warranty as standard

No registration. No extra cost. Just peace of mind from day one. Learn more.

Simple, reliable flow control

Applications involving the flow of water demand extreme reliability and low energy consumption. Control Techniques’ F600 drive, part of the newly introduced Specialist series of industry-specific drive technologies, builds on our company’s five decades of drives expertise, delivering precise, dependable flow control.

Everything you need is baked into the drive itself. The F600 packs all of the features you’ll need, presented using terminology you’ll understand. This isn’t a generic drive with pump features tacked on; it’s a dedicated, specialist pump drive, designed from the ground up to deliver the reliability and efficiency you need.

Introducing The Specialist Pump Drive, from the drive specialists

The perfect mix of application-specific features developed into a single solution

Speaks your languageThe F600 drive is tuned to suit your every need, optimised for minimal setup time yet sacrificing none of the flexibility. Whatever the challenge, our dedicated approach to clear parameter naming and structuring ensures we not only have the answers, but in a format you’ll understand. |

|

|

Energy savings, unlocking the potentialOn average, 85% of a pump’s life-cycle cost is attributed to its energy consumption, therefore, optimising the energy usage can mean a significant reduction in the total cost of ownership. The F600 drive thrives on delivering more efficient ways of operating your variable torque application. You’ll see the benefits in reduced running costs and lower energy requirements. |

|

Total controlThe F600 can also control the most efficient motors available, meeting IE5 efficiency levels, such as the Nidec Leroy Somer Dyneo+ hybrid permanent-magnet motor. With all of this combined, the F600 is your best choice to save you money every day. |

|

Engineered for your applicationThe F600 Pump Drive offers a host of dedicated features including dry-run prevention, pipe fill, pump cleaning, over-cycling protection and level switch control. A range of different control modes covering single pumps and also different parallel pump configurations make Control Techniques’ F600 a truly versatile solution. |

Free 5 year warranty To share our confidence in the reliability of Control Techniques, drives in the F600 range are eligible for Control Techniques’ extended warranty, at no extra cost. |

Download the brochure for detailed features and specifications

Free Standing Drive Range

Ready to use pre-engineered high power drives

Highly efficient pre-engineered motor control system

Control Techniques’ Free Standing Drive optimizes motor energy efficiency and comes ready to use, ore-assembled in its own industry-standard cabinet with all necessary system components included. The Pump Drive F600’s Free Standing Drive variant complements and extends the product range, while having all of the core product’s capabilities and features.

No extra engineering required

The Free Standing Drive fits a small footprint, and it’s easy to integrate with common enclosures, including as standard: load switch, fuses, fan, line and sharing chokes and cabling. The enclosures will soon be available with an optional door-mounted HMI, for easy set-up and maintenance.

Thanks to the dedicated online configurator, getting a quote and ordering is as simple as can be. Even more, we can ship your Free Standing Drive to you at very short lead times, saving weeks on typical industry standards.

Pump Drive F600 IP65

The Pump Drive F600 offers a full IP65 solution with exactly the same dedicated pump features & capabilities as the standard models.

IP65 provides protection from total dust ingress and low pressure water jets from any direction, making it a simple choice for harsh environments and the outdoors*. The Pump Drive F600 is now one of the most protected drives on the market, maximising pump uptime and productivity, while cutting maintenance costs.

Standard and High IP drives

The High IP drive will already be familiar to users of the F600, with all the same features that make commissioning effortless. The Hand-Off-Auto keypad with the built-in real-time clock is still available, sealed, and the protective casing has been designed with easy servicing and usability in mind. This new variant enables customers to use both standard and high IP drives for the same project, so there is no longer any headache with mixing-and-matching vendors or product feature sets, making project qualification straightforward.

Save on installation

The F600 High IP drive is enclosed in a sturdy, protective yet light casing, providing a compact solution. This not only allows easy integration in harsh environments but wall mounting close to the pump reduces installation costs, through:

- No cabinet required

- Shorter cable lengths

- Less labour time/cost to install drive

Free 5 year warranty

To share our confidence in the reliability of Control Techniques, the Pump Drive F600 High IP product is also eligible for Control Techniques’ extended warranty, at no extra cost.

*Shading from direct sunlight is required

Warranty terms and conditions apply.

Features

Unmatched total cost of ownership

With innovative protective features and extended equipment life

The F600 has comprehensive pump and motor protection features which minimise unplanned downtime, improving overall effectiveness and guaranteeing better value for money. Bring true resilience to your application and easily ride-through component failures.

Automatic Error Recovery

In the unlikely event of detecting an error with your pump, the F600 has the ability to dynamically recover and resume normal operation.

Limit Protection

If the feedback exceeds the limits defined for your application, the F600 has the ability to raise an alarm or stop the drive to protect your equipment and preserve its lifetime.

Transducer Loss Protection

In the event of losing connection to the transducer, the F600 can stop, continue to run at a fixed speed or ignore the fault depending on the application requirements.

Fire mode

Fire mode allows the drive to disable all trips and to continue to run uninterrupted during emergency events if the application requires.

Save on energy through a wide range of energy features

The F600 is 98% efficient, meaning very little energy is lost in power conversion.

Even more, the real savings potential gets unlocked by the F600’s built-in features that can further reduce energy consumption:

Low load savings

The F600 helps maximise energy savings when demand is low. Activing Control Techniques’ leading-edge Low Load Power Saving function, the drive dynamically reduces the voltage applied to reduce losses in the motor and make the system more efficient.

Sleep mode

When demand falls below a specified set-point the drive will automatically enter sleep mode and restart itself once demand rises above the set-point. Not only does this greatly reduce the amount of energy consumed, it also saves on equipment wear to preserve its lifetime.

The F600 features optimised control for your flow applications

Pipe fill

Prevent spikes in pressure at start-up using a controlled ramp, to protect your piping system and the pump itself.

Dry-run prevention

Prevent the pump running dry by checking the load against a threshold; with flexible configurations to dynamically adjust output, set an alarm or stop the drive.

Over-cycling protection

Optimise drive, motor and pump sizing, and regulate pump wear by limiting the number of start-stops per hour. Flexible configurations allow to dynamically alter cycling reference limits, set an alarm or stop the drive when a limit is reached.

No-flow detection

Where there is no-flow or low-flow, the F600 drive can automatically enter sleep mode to save energy, based on the feedback of a pulsed flow transducer, or triggered by a flow switch, or detected by the software alone.

Cleaning

Live, continuous monitoring of the system is used to trigger an automatic drive-based cleansing cycle to clear the pump impeller and help avoid maintenance costs on cleaning pump blockages.

Level switch control

Level switches provide critical protection for tanks in the event of the level reaching a “high” switch, whereby the pump is stopped, or a “low” switch, whereby the pump is started, to ensure pumping within tank levels.

Pump Control Modes | Flexible support for every system

Single pump

Control Techniques’ Single Pump mode is an effective and versatile variable speed control solution for maintaining a constant set-point in a single pump configuration.

- Fire mode allows the drive to disable all trips and to continue to run uninterrupted during emergency events if the application requires

Cascade

Cascade mode allows the F600 to operate with up to 2 assist pumps to aid the primary pump when required.

- Energy usage is optimised whereby the assist pumps are only enabled when demand reaches sufficient levels.

- Assist pumps are used alternately to apply uniform wear and increase pump availability.

- Over-cycling protection for assist pumps to control the number of starts and stops per hour.

Multi-leader

Complete control of your application with up to 3 x F600 drives and maximum energy savings with these variable frequency drives running parallel.

- The Multi-leader drive configuration provides redundancy and removes the need for a PLC

- The “lead” drive is automatically cycled to apply uniform wear

- If the “lead” drive loses its transducer, it can access the transducer feedback from another F600 in the system over Ethernet

- Dynamic re-selection of “lead” pump if a pump is taken out of service or develops a fault

Download the brochure for detailed features and specifications

Software

|

Connect is our latest drive configuration tool for commissioning, optimising and monitoring drive/system performance. Learn More |

Pump Drive F600 ratings guide

| 200/240 Vac ±10% | |||

| Drive | Normal Duty | ||

| Max continuous current (A) |

Motor shaft |

Motor shaft power (hp) |

|

| F600-03200066A10 | 6.6 | 1.1 | 1.5 |

| F600-03200080A10 | 8 | 1.5 | 2 |

| F600-03200110A10 | 11 | 2.2 | 3 |

| F600-03200127A10 | 12.7 | 3 | 3 |

| F600-04200180A10 | 18 | 4 | 5 |

| F600-04200250A10 | 25 | 5.5 | 7.5 |

| F600-05200300A10 | 30 | 7.5 | 10 |

| F600-06200500A10 | 50 | 11 | 15 |

| F600-06200580A10 | 58 | 15 | 20 |

| F600-07200750A10 | 75 | 18.5 | 25 |

| F600-07200940A10 | 94 | 22 | 30 |

| F600-07201170A10 | 117 | 30 | 40 |

| F600-08201490A10 | 149 | 37 | 50 |

| F600-08201800A10 | 180 | 45 | 60 |

| F600-09202160A10 | 216 | 55 | 75 |

| F600-09202660A10 | 266 | 75 | 100 |

| F600-09202160E10 | 216 | 55 | 75 |

| F600-09202660E10 | 266 | 75 | 100 |

| F600-10203250E10 | 325 | 90 | 125 |

| F600-10203600E10 | 360 | 110 | 150 |

| 380/480 Vac ±10% | |||

| Drive | Normal Duty | ||

| Max continuous current (A) |

Motor shaft power (kW) |

Motor shaft power (hp) |

|

| F600-03400034A10 | 3.4 | 1.1 | 1.5 |

| F600-03400045A10 | 4.5 | 1.5 | 2 |

| F600-03400062A10 | 6.2 | 2.2 | 3 |

| F600-03400077A10 | 7.7 | 3 | 5 |

| F600-03400104A10 | 10.4 | 4 | 5 |

| F600-03400123A10 | 12.3 | 5.5 | 7.5 |

| F600-04400185A10 | 18.5 | 7.5 | 10 |

| F600-04400240A10 | 24 | 11 | 15 |

| F600-05400300A10 | 30 | 15 | 20 |

| F600-06400380A10 | 38 | 18.5 | 25 |

| F600-06400480A10 | 48 | 22 | 30 |

| F600-06400630A10 | 63 | 30 | 40 |

| F600-07400790A10 | 79 | 37 | 50 |

| F600-07400940A10 | 94 | 45 | 60 |

| F600-07401120A10 | 112 | 55 | 75 |

| F600-08401550A10 | 155 | 75 | 100 |

| F600-08401840A10 | 184 | 90 | 125 |

| F600-09402210A10 | 221 | 110 | 150 |

| F600-09402660A10 | 266 | 132 | 200 |

| F600-09402210E10 | 221 | 110 | 150 |

| F600-09402660E10 | 266 | 132 | 200 |

| F600-10403200E10 | 320 | 160 | 250 |

| F600-10403610E10 | 361 | 200 | 300 |

| F600-11404370E10 | 437 | 225 | 350 |

| F600-11404870E10 | 487 | 250 | 400 |

| F600-11405070E10 | 507 | 280 | 450 |

| 380/480 Vac ±10% | |||

| Drive | Normal Duty | ||

| Max continuous current (A) |

Motor shaft power (kW) |

Motor shaft power (hp) |

|

| F600-12404800TU0 | 608 | 315 | 500 |

| F600-12405660TU0 | 660 | 355 | 550 |

| F600-12406600TU0 | 755 | 400 | 650 |

| F600-12407200TU0 | 865 | 500 | 700 |

| 500/575 Vac ±10% | |||

| Drive | Normal Duty | ||

| Max continuous current (A) |

Motor shaft power (kW) |

Motor shaft power (hp) |

|

| F600-05500039A10 | 3.9 | 2.2 | 3 |

| F600-05500061A10 | 6.1 | 4 | 5 |

| F600-05500100A10 | 10 | 5.5 | 7.5 |

| F600-06500120A10 | 12 | 7.5 | 10 |

| F600-06500170A10 | 17 | 11 | 15 |

| F600-06500220A10 | 22 | 15 | 20 |

| F600-06500270A10 | 27 | 18.5 | 25 |

| F600-06500340A10 | 34 | 22 | 30 |

| F600-06500430A10 | 43 | 30 | 40 |

| F600-07500530A10 | 53 | 37 | 50 |

| F600-07500730A10 | 73 | 45 | 60 |

| F600-08500860A10 | 86 | 55 | 75 |

| F600-08501080A10 | 108 | 75 | 100 |

| F600-09501250A10 | 125 | 90 | 125 |

| F600-09501550A10 | 155 | 110 | 150 |

| F600-09501250E10 | 125 | 90 | 125 |

| F600-09501500E10 | 150 | 110 | 150 |

| F600-10502000E10 | 200 | 130 | 200 |

| F600-11502480E10 | 248 | 175 | 250 |

| F600-11502880E10 | 288 | 225 | 300 |

| F600-11503150E10 | 315 | 250 | 350 |

| 500/690 Vac ±10% | |||

| Drive | Normal Duty | ||

| Max continuous current (A) |

Motor shaft power (kW) |

Motor shaft power (hp) |

|

| F600-07600230A10 | 23 | 18.5 | 25 |

| F600-07600300A10 | 30 | 22 | 30 |

| F600-07600360A10 | 36 | 30 | 40 |

| F600-07600460A10 | 46 | 37 | 50 |

| F600-07600520A10 | 52 | 45 | 60 |

| F600-07600730A10 | 73 | 55 | 75 |

| F600-08600860A10 | 86 | 75 | 100 |

| F600-08601080A10 | 108 | 90 | 125 |

| F600-09601250A10 | 125 | 110 | 150 |

| F600-09601500A10 | 150 | 132 | 175 |

| F600-09601250E10 | 125 | 110 | 150 |

| F600-09601550E10 | 155 | 132 | 175 |

| F600-10601720E10 | 172 | 160 | 200 |

| F600-10601970E10 | 197 | 185 | 250 |

| F600-11602250E10 | 225 | 200 | 250 |

| F600-11602750E10 | 275 | 250 | 300 |

| F600-11603050E10 | 305 | 280 | 400 |

Normal duty operation only

Suitable for pump applications, with a current overload requirement of 110% for 60 s*.

Conformance

- IP20 / NEMA1 / UL TYPE 1 *UL open class as standard, additional kit needed to achieve Type 1

- IP65 / NEMA4 / UL TYPE 12 rating is achieved on the rear of the drive when through panel mounted

- *Frame size 9D, 9E, 10D and 10E achieve IP55 / NEMA 4 / UL Type 12

- Ambient temperature -20 °C to 40 °C (-4 °F to 104 °F) as standard. Up to 55 °C (131 °F) with derating

- Humidity 95 % maximum (non-condensing) at 40 °C (104 °F)

- Altitude: 0 to 3000 m (9900 ft), derate 1 % per 100 m (330 ft) between 1000 m (3300 ft) and 3000 m (9900 ft)

- Random Vibration Tested in accordance with IEC 60068-2-64

- Bump Tested in accordance with IEC 60068-2-29

- Sinusoidal Vibration Tested in accordance with IEC 60068-2-6

- Mechanical Shock Tested in accordance with IEC 60068-2-29

- Storage temperature -40 °C to 55 °C (-40 °F to 131 °F) or up to 70 °C (158 °F) for short-term storage

- Electromagnetic Immunity complies with EN 61800-3 and EN 61000-6-2

- With onboard EMC filter, emissions comply with EN 61800-3 (category C3)

- EN 61000-6-3 and EN 61000-6-4 with optional footprint EMC filter

- IEC 60146-1-1 Supply conditions (category C1 or C2 depending on rating)

- IEC 61800-5-1 (Electrical Safety)

- IEC 61131-2 I/O

- EN 61000-3-12 with optional line reactor

- UL 508C (Electrical Safety)

Approval & Listings

|

cUL |

USA and Canada (cUL Listed). UL File number: E171230 |

|

CE |

European Union (all applicable directives and regulations LVD, EMD, RoHS, REACH, Energy related products) |

|

UKCA |

United Kingdom (all applicable regulations) |

|

RCM |

Australia and New Zealand (Responsible Supplier Registration No. E6934) |

|

EAC |

Russian Customs Union. All Unidrive-M models |

| DNV Marine approval |

F600 models |

|

Functional Safety |

Safe Torque Off function. TÜV Rheinland Type Examination Certificates: 01/205/5270.02/17 (Unidrive-M and derivative products) 01/205/5409.02/21 (SI-Safety option module) 01/205/5720.00/19 (MiS210, MiS250 option modules) The safety function “Safe Torque Off” can be used in applications up to Cat 4. PL e according to EN ISO 13849-1, SIL 3 according to EN 61800-5-2/ EN 62061/ IEC 61508, and in lift applications according to EN 81-1 and EN81-2. |

| UL Functional Safety |

Unidrive-M all products |

|

ISO |

Quality system: ISO 9001 (Certificate Nos. FM 739405) |

|

China RoHS |

Chinese Order No. 32, 2016; Administrative Measures for the Restriction of Hazardous Substances in Electrical and Electronic Equipment (China RoHS 2), |

|

EPA TSCA regulations |

All Commander and Unidrive-M products |

|

IHM, Basel convention, |

MEPC 68/21 / Add.1, Annex 17, Resolution MEPC.269(68) 2015 Guidelines for the development of the inventory of hazardous materials. |

|

Responsible Minerals Initiative (RMI) |

CMRT compliance |

Weights & Dimensions

| Frame size | Dimensions | Weight | |

| mm (HxWxD) | in (HxWxD) | kg (lb) | |

| 3 | 382 x 83 x 200 | 15.0 x 3.3 x 7.9 | 4.5 (9.9) |

| 4 | 391 x 124 x 200 | 15.4 x 4.9 x 7.9 | 6.5 (14.3) |

| 5 | 391 x 143 x 200 | 15.4 x 5.6 x 7.6 | 7.4 (16.3) |

| 6 | 391 x 210 x 227 | 15.4 x 8.3 x 8.9 | 14 (30.9) |

| 7 | 557 x 270 x 280 | 21.9 x 10.6 x 11.0 | 28 (61.7) |

| 8 | 803 x 310 x 290 | 31.6 x 12.2 x 11.4 | 50 (110.2) |

| 9A | 1108 x 310 x 290 | 43.6 x 12.2 x 11.4 | 66.5 (146.6) |

| 9E/10E | 1069 x 310 x 290 | 42.1 x 12.2 x 11.4 | 46 (101.4) |

| 9D/10D |

Rectifier |

Rectifier 15.8 x 12.2 x 11.4 ———————– Inverter 30.4 x 12.2 x 11.4 |

|

| 11E | 1242 x 310 x 312 | 48.9 x 12.2 x 12.3 | 63 (138.9) |

| 12T | 1750 x 295 x 526 | 68.9 x 11.6 x 20.7 | 130 (287) |

*For more detailed information please see technical documents.

Keypads

|

KI-Keypad Plus Bluetooth allows remote and flexible connectivity for PC tool commissioning and programming, without needing to open the enclosure, for smarter and safer working. 10 user selectable parameters can be displayed on the status screen, with real-time information, plus all parameters can be scaled and their units customized. |

|

KI-HOA Keypad RTC (Supplied as standard*) The KI-HOA Keypad RTC provides Hand-Off-Auto control. The display presents up to four lines of real text with multilanguage translation, enhancing clarity and increasing ease of use. A battery operated real-time clock allows scheduling of run and off periods and adds accurate time stamping to diagnostics to aid rapid fault resolution. |

|

Remote HOA Keypad RTC Remote mountable keypad, allowing flexible mounting on the outside of a panel (meets IP54/NEMA 12). The keypad offers Hand-Off-Auto control and can present up to four lines of real text with multi language translation, enhancing clarity and increasing ease of use. Battery operated real-time clock allows scheduling of run and off periods and adds accurate time stamping to logged events, aiding diagnostics. |

|

|

KI-485 Adaptor This adaptor can be fit in place of the drive keypad and provides additional ports to communicate via RS485. The adaptor is commonly used for programming the drive. |

System integration modules – communications

|

SI-BACnet IP The new SI-BACnet IP option module provides enhanced control and maximum efficiency in building automation systems, ensuring accurate and co-ordinated operation to boost occupant comfort. |

|

SI-POWERLINK Connects Unidrive, Commander, Digitax and the Pump Drive families to all POWERLINK networks. SI-POWERLINK serves applications ranging from simple open-loop systems through to those demanding precise motion control. The protocol is based upon standard Ethernet and provides a solution for real-time Industrial Ethernet to satisfy the requirements of industrial automation and process control. |

|

SI-Ethernet External Ethernet module that supports EtherNet/IP and Modbus TCP/IP and has an integrated web server that can generate emails. The module can be used to provide high speed drive access, global connectivity and integration with IT network technologies, such as wireless networking. To use multiple F600 drives in Multi-leader mode in a parallel pump system, each F600 drive must have an SI-Ethernet module fitted. |

|

SI-EtherCAT SI-EtherCAT allows F600 to connect and interface with EtherCAT networks. |

|

SI-PROFINET SI-PROFINET allows F600 to communicate and interface with PROFINET PLCs and networks. |

|

SI-PROFIBUS PROFIBUS interface module PROFIBUS-DP (Decentralized Peripheral) interface module enables follower connectivity. It is possible to use more than one SI-PROFIBUS or a combination of SI-PROFIBUS and other option modules to add additional functionality such as extended I/O, gateway functionality, or additional PLC features. |

|

SI-DeviceNet DeviceNet networking system interface module enables follower connectivity. It is possible to use more than one SIDeviceNet or a combination of SI-DeviceNet and other option modules to provide additional functionality such as extended I/O, gateway functionality, or additional PLC features. |

|

SI-CANopen CANopen interface module supporting various profiles, including several drive profiles. |

|

MCi200 Second processor, providing advanced customisation using standard IEC61131-3 programming languages. |

|

MCi210 Adds to the MCi200 with a dual port Ethernet interface directly on the processor and additional I/O |

Additional I/O and NV media cards

|

SI-I/O |

|

Smartcard The optional Smartcard memory device can be used to back-up parameter sets, as well as copying them from one drive to another |

|

SD Card Adaptor Conversion device that allows an SD card to be inserted into the Smartcard slot, for parameter cloning and application programs |

*For higher cost efficiency, F600 can be supplied without a keypad.

Please specify your preference when ordering.

Brochures

Case Studies

Datasheets

Flyers

Product Catalog

Technical Documents, Software and Drawings

Videos

White Papers

This product comes with 5-year warranty as standard

No registration. No extra cost. Just peace of mind from day one. Learn more.

Simple, reliable flow control

Applications involving the flow of water demand extreme reliability and low energy consumption. Control Techniques’ F600 drive, part of the newly introduced Specialist series of industry-specific drive technologies, builds on our company’s five decades of drives expertise, delivering precise, dependable flow control.

Everything you need is baked into the drive itself. The F600 packs all of the features you’ll need, presented using terminology you’ll understand. This isn’t a generic drive with pump features tacked on; it’s a dedicated, specialist pump drive, designed from the ground up to deliver the reliability and efficiency you need.

Introducing The Specialist Pump Drive, from the drive specialists

The perfect mix of application-specific features developed into a single solution

Speaks your languageThe F600 drive is tuned to suit your every need, optimised for minimal setup time yet sacrificing none of the flexibility. Whatever the challenge, our dedicated approach to clear parameter naming and structuring ensures we not only have the answers, but in a format you’ll understand. |

|

|

Energy savings, unlocking the potentialOn average, 85% of a pump’s life-cycle cost is attributed to its energy consumption, therefore, optimising the energy usage can mean a significant reduction in the total cost of ownership. The F600 drive thrives on delivering more efficient ways of operating your variable torque application. You’ll see the benefits in reduced running costs and lower energy requirements. |

|

Total controlThe F600 can also control the most efficient motors available, meeting IE5 efficiency levels, such as the Nidec Leroy Somer Dyneo+ hybrid permanent-magnet motor. With all of this combined, the F600 is your best choice to save you money every day. |

|

Engineered for your applicationThe F600 Pump Drive offers a host of dedicated features including dry-run prevention, pipe fill, pump cleaning, over-cycling protection and level switch control. A range of different control modes covering single pumps and also different parallel pump configurations make Control Techniques’ F600 a truly versatile solution. |

Free 5 year warranty To share our confidence in the reliability of Control Techniques, drives in the F600 range are eligible for Control Techniques’ extended warranty, at no extra cost. |

Download the brochure for detailed features and specifications

Free Standing Drive Range

Ready to use pre-engineered high power drives

Highly efficient pre-engineered motor control system

Control Techniques’ Free Standing Drive optimizes motor energy efficiency and comes ready to use, ore-assembled in its own industry-standard cabinet with all necessary system components included. The Pump Drive F600’s Free Standing Drive variant complements and extends the product range, while having all of the core product’s capabilities and features.

No extra engineering required

The Free Standing Drive fits a small footprint, and it’s easy to integrate with common enclosures, including as standard: load switch, fuses, fan, line and sharing chokes and cabling. The enclosures will soon be available with an optional door-mounted HMI, for easy set-up and maintenance.

Thanks to the dedicated online configurator, getting a quote and ordering is as simple as can be. Even more, we can ship your Free Standing Drive to you at very short lead times, saving weeks on typical industry standards.

Pump Drive F600 IP65

The Pump Drive F600 offers a full IP65 solution with exactly the same dedicated pump features & capabilities as the standard models.

IP65 provides protection from total dust ingress and low pressure water jets from any direction, making it a simple choice for harsh environments and the outdoors*. The Pump Drive F600 is now one of the most protected drives on the market, maximising pump uptime and productivity, while cutting maintenance costs.

Standard and High IP drives

The High IP drive will already be familiar to users of the F600, with all the same features that make commissioning effortless. The Hand-Off-Auto keypad with the built-in real-time clock is still available, sealed, and the protective casing has been designed with easy servicing and usability in mind. This new variant enables customers to use both standard and high IP drives for the same project, so there is no longer any headache with mixing-and-matching vendors or product feature sets, making project qualification straightforward.

Save on installation

The F600 High IP drive is enclosed in a sturdy, protective yet light casing, providing a compact solution. This not only allows easy integration in harsh environments but wall mounting close to the pump reduces installation costs, through:

- No cabinet required

- Shorter cable lengths

- Less labour time/cost to install drive

Free 5 year warranty

To share our confidence in the reliability of Control Techniques, the Pump Drive F600 High IP product is also eligible for Control Techniques’ extended warranty, at no extra cost.

*Shading from direct sunlight is required

Warranty terms and conditions apply.

Features

Unmatched total cost of ownership

With innovative protective features and extended equipment life

The F600 has comprehensive pump and motor protection features which minimise unplanned downtime, improving overall effectiveness and guaranteeing better value for money. Bring true resilience to your application and easily ride-through component failures.

Automatic Error Recovery

In the unlikely event of detecting an error with your pump, the F600 has the ability to dynamically recover and resume normal operation.

Limit Protection

If the feedback exceeds the limits defined for your application, the F600 has the ability to raise an alarm or stop the drive to protect your equipment and preserve its lifetime.

Transducer Loss Protection

In the event of losing connection to the transducer, the F600 can stop, continue to run at a fixed speed or ignore the fault depending on the application requirements.

Fire mode

Fire mode allows the drive to disable all trips and to continue to run uninterrupted during emergency events if the application requires.

Save on energy through a wide range of energy features

The F600 is 98% efficient, meaning very little energy is lost in power conversion.

Even more, the real savings potential gets unlocked by the F600’s built-in features that can further reduce energy consumption:

Low load savings

The F600 helps maximise energy savings when demand is low. Activing Control Techniques’ leading-edge Low Load Power Saving function, the drive dynamically reduces the voltage applied to reduce losses in the motor and make the system more efficient.

Sleep mode

When demand falls below a specified set-point the drive will automatically enter sleep mode and restart itself once demand rises above the set-point. Not only does this greatly reduce the amount of energy consumed, it also saves on equipment wear to preserve its lifetime.

The F600 features optimised control for your flow applications

Pipe fill

Prevent spikes in pressure at start-up using a controlled ramp, to protect your piping system and the pump itself.

Dry-run prevention

Prevent the pump running dry by checking the load against a threshold; with flexible configurations to dynamically adjust output, set an alarm or stop the drive.

Over-cycling protection

Optimise drive, motor and pump sizing, and regulate pump wear by limiting the number of start-stops per hour. Flexible configurations allow to dynamically alter cycling reference limits, set an alarm or stop the drive when a limit is reached.

No-flow detection

Where there is no-flow or low-flow, the F600 drive can automatically enter sleep mode to save energy, based on the feedback of a pulsed flow transducer, or triggered by a flow switch, or detected by the software alone.

Cleaning

Live, continuous monitoring of the system is used to trigger an automatic drive-based cleansing cycle to clear the pump impeller and help avoid maintenance costs on cleaning pump blockages.

Level switch control

Level switches provide critical protection for tanks in the event of the level reaching a “high” switch, whereby the pump is stopped, or a “low” switch, whereby the pump is started, to ensure pumping within tank levels.

Pump Control Modes | Flexible support for every system

Single pump

Control Techniques’ Single Pump mode is an effective and versatile variable speed control solution for maintaining a constant set-point in a single pump configuration.

- Fire mode allows the drive to disable all trips and to continue to run uninterrupted during emergency events if the application requires

Cascade

Cascade mode allows the F600 to operate with up to 2 assist pumps to aid the primary pump when required.

- Energy usage is optimised whereby the assist pumps are only enabled when demand reaches sufficient levels.

- Assist pumps are used alternately to apply uniform wear and increase pump availability.

- Over-cycling protection for assist pumps to control the number of starts and stops per hour.

Multi-leader

Complete control of your application with up to 3 x F600 drives and maximum energy savings with these variable frequency drives running parallel.

- The Multi-leader drive configuration provides redundancy and removes the need for a PLC

- The “lead” drive is automatically cycled to apply uniform wear

- If the “lead” drive loses its transducer, it can access the transducer feedback from another F600 in the system over Ethernet

- Dynamic re-selection of “lead” pump if a pump is taken out of service or develops a fault

Download the brochure for detailed features and specifications

Software

|

Connect is our latest drive configuration tool for commissioning, optimising and monitoring drive/system performance. Learn More |

Sản phẩm tương tự

Specialist Drives

Servo Drives

General Purpose AC Drives

Servo Drives

Servo Drives

High Performance AC Drives

General Purpose AC Drives

CONTROL TECHNIQUES