IMS12-04BPSNC0S

Inductive proximity sensors

IMS

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

-

Features

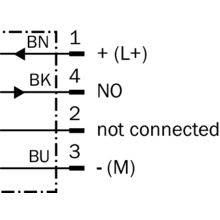

Housing Cylindrical thread design Housing Standard design Thread size M12 x 1 Diameter Ø 12 mm Sensing range Sn 4 mm Safe sensing range Sa 3.24 mm Installation type Flush Switching frequency 2,000 Hz Connection type Male connector M12, 4-pin 1) Switching output PNP Output function NO Electrical wiring DC 3-wire Enclosure rating IP68 2)

IP69K 3)

Special features Resistant to cleaning agents, Temperature resistance Special applications Mobile machines, Hygienic and washdown zones, Difficult application conditions Items supplied Mounting nut, brass, nickel-plated (2x) - 1) With gold plated contact pins.

- 2) According to EN 60529.

- 3) According to ISO 20653:2013-03.

-

Mechanics/electronics

Supply voltage 7.2 V DC … 60 V DC Ripple ≤ 10 % Voltage drop ≤ 2.5 V 1) Time delay before availability 100 ms Hysteresis 3 % … 20 % Reproducibility ≤ 2 % 2) Temperature drift (of Sr) ± 10 % EMC Emitted interference and interference immunity in accordance with Motor Insurance Directive ECE-R10 Rev. 5: E1-Type approval

Interference immunity in accordance with DIN ISO 11452-2: 100 V/m

AM vertical 20 MHz – 800 MHz; AM horizontal 200 MHz – 800 MHz; PM vertical/horizontal 800 MHz – 2.7 GHz

Conducted disturbances in accordance with ISO 7637-2 (pulse/severity/failure criterion 12 V/failure criterion 24 V): 1/IV/C/C, 2a/IV/A/A, 2b/IV/C/C, 3a/IV/A/A, 3b/IV/A/A, 4/IV/C/A, 5a/IV/B/B, 5b/IV/B/B

EN 61000-4-2 ESD: 4 kV CD / 8 kV AD

EN 61000-4-3 HF radiated: 10 V/m

EN 61000-4-4 burst: 2 kV

EN 61000-4-5 surge: 0,5 kV L-to-L, Ri: 2 Ohm

EN 61000-4-6 HF wire-bound: 10 V/m

Environmental test Quick temperature change EN 60068-2-14, Na: TA = –25 °C, TB = 75 °C, t1 = 40 min, t2 = < 10 s, 300 cycles, Delta Sr ≤ 10% Corrosion test Salt spray test EN 60068-2-52: severity 5, 4 cycles Continuous current Ia ≤ 200 mA 3) No load current ≤ 10 mA Short-circuit protection ✔ Reverse polarity protection ✔ Power-up pulse protection ✔ Shock and vibration resistance Vibration resistance EN 60068-2-6 Fc: 25 g peak (10 Hz … 2,000 Hz) / –20 °C … +50 °C

Shock resistance EN 60068-2-27 Ea: 100 g 11 ms; 3 shocks in every direction of the 3 coordinate axes / –40 °C … +85 °C

Continuous shock resistance EN 60068-2-29 Eb: 40 g 3 ms rise, 7 ms fall / 5,000 shocks in every direction of the 3 coordinate axes / -20 °C … +50 °C

Broadband noise EN 60068-2-64: 15 g rms (5 Hz … 2,000 Hz) / 8 hours in every direction of the 3 coordinate axes / –40 °C … +85 °C

Ambient operating temperature –40 °C … +100 °C Housing material Stainless steel V4A, DIN 1.4404 / AISI 316L Sensing face material Plastic, LCP Housing length 65 mm Thread length 48 mm Tightening torque, max. Typ. 20 Nm Protection class III UL File No. E181493 - 1) At Ia max.

- 2) Ub and Ta constant.

- 3) See “Continuous current Ia above temperature” characteristic curve.

-

Safety-related parameters

MTTFD 1,196 years DCavg 0 %

-

Reduction factors

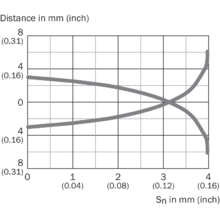

Note The values are reference values which may vary Stainless steel (V2A, 304) Approx. 0.65 Aluminum (Al) Approx. 0.35 Copper (Cu) Approx. 0.24 Brass (Br) Approx. 0.38

-

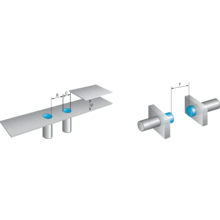

Installation note

Remark Associated graphic see “Installation” B 12 mm C 12 mm D 12 mm F 32 mm

-

Classifications

eCl@ss 5.0 27270101 eCl@ss 5.1.4 27270101 eCl@ss 6.0 27270101 eCl@ss 6.2 27270101 eCl@ss 7.0 27270101 eCl@ss 8.0 27270101 eCl@ss 8.1 27270101 eCl@ss 9.0 27270101 eCl@ss 10.0 27270101 eCl@ss 11.0 27270101 eCl@ss 12.0 27274001 ETIM 5.0 EC002714 ETIM 6.0 EC002714 ETIM 7.0 EC002714 ETIM 8.0 EC002714 UNSPSC 16.0901 39122230

Sản phẩm tương tự

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors

Inductive proximity sensors