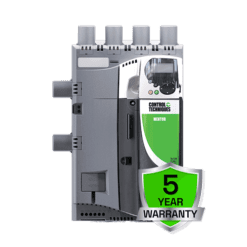

Elevator Drive E300 AC Drives

Elevator Drive E300 AC Drives

Specialist AC Drive

3 – 400 hp (2.2 kW – 250 kW)

230 V | 460 V | 575 V | 690 V

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

This product comes with 5-year warranty as standard

No registration. No extra cost. Just peace of mind from day one. Learn more.

Dedicated Drives For Class-Leading Ride Comfort

Contact us for assistance or with questions

Our elevator drive solutions work for any size of building. Whether it’s a small residential building or a luxury high rise, new build or modernization projects, we make every step of the process as easy as possible from product selection to installation, setup and service.

Introducing the dedicated Elevator Drive

Adding value at every stage of your project

|

Freedom to design

|

|

Effortless installation and commissioning

|

|

Class-leading performance

|

|

Maintenance and diagnostics support

|

Features

Rapid set-up and adjustment

- Simple and intuitive parameter adjustment via a bright back-lit LCD keypad

- Set-up in familiar elevator language and units

- Easy to use menu structure for quick and simple access to key adjustments

- Top level menu; all your frequently needed functions in one location

- No de-roping for encoder phasing test, no need to rotate motor

Optimum ride comfort

- Direct-to-floor positioning

- Peak curve operation

- High resolution multi-step S-ramp for start, run, slowdown and stopping

- Ultra-fast current loop for vibration free motor control

- Advanced brake control management, no rollback on starting without the need of load sensor

Silent operation

- No motor contactors required, advanced EN81-1/2 TÜV certified STO enable input

- High switching frequencies selectable up to 16 kHz

- Variable speed cooling fan

Energy efficient

- Standby sleep/wake mode, powers down unused circuitry during prolonged periods of standby

- Easy connection to a range of regenerative modules

Flexible integration

- Modbus RTU communications

- Parallel I/O interface

- +/- 10V analog reference control

- Direct RS485 comms control

- Tile mount for low profile shaft mounting

- 24 Vdc backup

- Simple UPS connection with load direction signal

- Dynamic braking transistor fitted to all drives as standard

Robust

- Active thermal management for tripless operation under extreme conditions

- Advanced power circuit design using latest IGBT technology

- Conformal coating for use in harsh environments

- Building on the market leading position as the industry’s most robust drive

- Phase loss detection on both input and output

Enhanced elevator data logger

- User configurable, for example speed reference, speed feedback, current and I/O sequence can all be recorded for every car journey

- Can be stored in the event of system fault

- Available for offline viewing to aid system diagnostics

Commissioning and monitoring software

Elevator Connect PC Tool – CommissioningThe Connect PC Tool configures, optimizes and monitors drive/system control and performance |

Key data

- Dedicated Elevator drive

Standard features

Onboard comms

- RS485 communications port MODBUS RTU with integrated command word and built in watchdog

Safety

- 1 x Safe Torque Off (STO) terminal

- SIL3/PLe compliant

Keypad

- Dedicated elevator keypad supplied as standard, providing:

Option slots

- 3

Parameter cloning via

- PC tools

- Smartcard

- SD card

Approval & Listings

|

cUL |

USA and Canada (cUL Listed). UL File number: E171230 |

|

CE |

European Union (all applicable directives and regulations LVD, EMD, RoHS, REACH, Energy related products) |

|

UKCA |

United Kingdom (all applicable regulations) |

|

RCM |

Australia and New Zealand (Responsible Supplier Registration No. E6934) |

|

EAC |

Russian Customs Union. E300 models |

|

Functional Safety |

Safe Torque Off function. TÜV Rheinland Type Examination Certificates: 01/205/5270.02/17 (Unidrive-M and derivative products) 01/205/5409.02/21 (SI-Safety option module) 01/205/5720.00/19 (MiS210, MiS250 option modules) The safety function “Safe Torque Off” can be used in applications up to Cat 4. PL e according to EN ISO 13849-1, SIL 3 according to EN 61800-5-2/ EN 62061/ IEC 61508, and in lift applications according to EN 81-1 and EN81-2. |

| UL Functional Safety | Unidrive-M all products File E171230 Vol. 11 Sec. 1 Issued: 2015-01-22 Compliance with specific requirements of NFPA 79 |

| Functional Safety for Elevators | TÜV Nord certificates

44 799 17002401 (Brake contact monitoring feature, E300 series drives) |

|

ISO |

Quality system: ISO 9001 (Certificate Nos. FM 739405) Environmental management system: ISO 14001 (Certificate No. EMS 739789) Occupational health and safety: ISO 45001 (Certificate No. 5430) |

|

China RoHS |

Chinese Order No. 32, 2016; Administrative Measures for the Restriction of Hazardous Substances in Electrical and Electronic Equipment (China RoHS 2), |

|

EPA TSCA regulations |

All Commander and Unidrive-M products U.S. Environmental Protection Agency (“EPA”) recently promulgated regulations under the Toxic Substances Control Act (“TSCA”) |

|

IHM, Basel convention, |

MEPC 68/21 / Add.1, Annex 17, Resolution MEPC.269(68) 2015 Guidelines for the development of the inventory of hazardous materials. |

|

Responsible Minerals Initiative (RMI) |

CMRT compliance |

380 – 480 Vac, 50-60 Hz ± 10 % Drive Ratings

| PART NUMBER | CURRENT (A) | |

|---|---|---|

| PEAK CURRENT | NOMINAL CURRENT | |

| 03400062A10 | 11 | 6.2 |

| 03400078A10 |

14

|

7.8 |

| 03400100A10 | 18 | 10 |

| 04400150A10 | 27 | 15 |

| 04400172A10 | 31 | 17.2 |

| 05400220A10 | 39 | 22 |

| 05400270A10 | 48 | 27 |

| 05400300A10 | 53 | 30 |

| 06400350A10 | 62 | 35 |

| 06400420A10 | 74 | 42 |

| 06400470A10 | 83 | 47 |

| 07400660A10 | 116 | 66 |

| 07400770A10 | 135 | 77 |

| 07401000A10 | 175 | 100 |

| 08401340A10 | 235 | 134 |

| 08401570A10 | 275 | 157 |

| 09402000A10 | 350 | 200 |

| 09402240A10 | 385 | 220 |

| 10402700E | 473 | 270 |

| 10403200E | 543 | 310 |

Switching frequency 8 KHz (selectable 3 to 16 kHz @ 50 % ED)

Braking transistor built in as standard

200 – 240 Vac, 50-60 Hz ± 10 % Drive Ratings

| PART NUMBER | CURRENT (A) | |

|---|---|---|

| PEAK CURRENT | NOMINAL CURRENT | |

| 03200106A10 | 21.2 | 10.6 |

| 04200137A10 | 27.4 | 13.7 |

| 04200185A10 | 37 | 18.5 |

| 05200250A10 | 50 | 25 |

| 06200330A10 | 66 | 33 |

| 06200440A10 | 88 | 44 |

| 07200610A10 | 122 | 61 |

| 07200750A10 | 150 | 75 |

| 07200830A10 | 166 | 83 |

| 08201160A10 | 232 | 116 |

| 08201320A10 | 264 | 132 |

| 09201760A10 | 352 | 176 |

| 09202190A10 | 438 | 219 |

| 10202830A | 566 | 283 |

| 10203000A | 600 | 300 |

For all above

Switching frequency 8 KHz (selectable 3 to 16 kHz @ 50 % ED)

Braking transistor built in as standard

Further information from your supplier is available on the following features:

• UPS operation – all drives have a dedicated rescue mode allowing operation from 200 V UPS

• DC supply – all drives have the possibility of being supplied from a DC source from 24 V to the maximum voltage rating of the product

• 500 V, 525 V, 575 V and 690 V units are also available

Keypads

|

KI-Keypad PlusKI-Keypad Plus’ large and clear color display makes the drive status information and parameter descriptions easy to read and readily accessible. It enables easy access to key drive features for enhanced machine performance, with the helpful wizard quickly guiding the user through configuration. Bluetooth allows remote and flexible connectivity for PC tool commissioning and programming, without needing to open the enclosure, for smarter and safer working. 10 user selectable parameters can be displayed on the status screen, with real-time information, plus all parameters can be scaled and their units customized. |

|

Remote keypad RTCRemote mountable keypad, allowing flexible mounting on the outside of a panel (meets IP54/NEMA 12). The keypad offers a four line plain text, multi-language LCD display for rapid set-up and helpful diagnostics. A battery operated real-time clock allows accurate time stamping of events, aiding diagnostics. |

System Integration Modules – Communications

|

SI-DCPDCP interface module |

|

SI-CANopenCANopen interface module supporting various profiles, including several drive profiles |

System Integration Modules – Feedback

|

SI-Encoder Quadrature encoder input interface module |

|

SI-Universal Encoder Encoder input and output interface supporting Quadrature, SinCos, EnDat and SSI encoders |

System Integration Modules – Applications

|

SI-ApplicationsSecond processor module, which allows SyPTPro application programs to be re-compiled for Unidrive M700. |

|

MCi200Second processor, providing advanced machine control using Machine Control Studio. |

|

MCi210Adds to the MCi200 with a dual port Ethernet interface directly on the processor and additional I/O |

System Integration Modules – Additional I/O

|

SI-I/OExtended I/O interface module to increase the number of I/O points on a drive. Provides additional: 4 x Digital I/O, 3 x Analog inputs (default)/Digital inputs, 1 x Analog output (default)/Digital input, 2 x Relays |

Drive interface units – Backup

|

SmartcardSmartcard memory device to backup and copy parameter sets and basic PLC programs. |

|

SD Card AdaptorAllows an SD card to be inserted into the Smartcard slot, for parameter backup cloning and application programs. |

Drive interface units – Communications

|

KI-485 AdaptorThis allows the drive to communicate via RS485. This is commonly used for programming if the drive has no keypad |

|

CT USB Comms cableThe USB Comms cable allows the drive to connect to a PC for use with Unidrive M’s PC tools. |

Brochures

Case Studies

Datasheets

Flyers

Product Catalog

Technical Documents, Software and Drawings

Videos

White Papers

This product comes with 5-year warranty as standard

No registration. No extra cost. Just peace of mind from day one. Learn more.

Dedicated Drives For Class-Leading Ride Comfort

Contact us for assistance or with questions

Our elevator drive solutions work for any size of building. Whether it’s a small residential building or a luxury high rise, new build or modernization projects, we make every step of the process as easy as possible from product selection to installation, setup and service.

Introducing the dedicated Elevator Drive

Adding value at every stage of your project

|

Freedom to design

|

|

Effortless installation and commissioning

|

|

Class-leading performance

|

|

Maintenance and diagnostics support

|

Features

Rapid set-up and adjustment

- Simple and intuitive parameter adjustment via a bright back-lit LCD keypad

- Set-up in familiar elevator language and units

- Easy to use menu structure for quick and simple access to key adjustments

- Top level menu; all your frequently needed functions in one location

- No de-roping for encoder phasing test, no need to rotate motor

Optimum ride comfort

- Direct-to-floor positioning

- Peak curve operation

- High resolution multi-step S-ramp for start, run, slowdown and stopping

- Ultra-fast current loop for vibration free motor control

- Advanced brake control management, no rollback on starting without the need of load sensor

Silent operation

- No motor contactors required, advanced EN81-1/2 TÜV certified STO enable input

- High switching frequencies selectable up to 16 kHz

- Variable speed cooling fan

Energy efficient

- Standby sleep/wake mode, powers down unused circuitry during prolonged periods of standby

- Easy connection to a range of regenerative modules

Flexible integration

- Modbus RTU communications

- Parallel I/O interface

- +/- 10V analog reference control

- Direct RS485 comms control

- Tile mount for low profile shaft mounting

- 24 Vdc backup

- Simple UPS connection with load direction signal

- Dynamic braking transistor fitted to all drives as standard

Robust

- Active thermal management for tripless operation under extreme conditions

- Advanced power circuit design using latest IGBT technology

- Conformal coating for use in harsh environments

- Building on the market leading position as the industry’s most robust drive

- Phase loss detection on both input and output

Enhanced elevator data logger

- User configurable, for example speed reference, speed feedback, current and I/O sequence can all be recorded for every car journey

- Can be stored in the event of system fault

- Available for offline viewing to aid system diagnostics

Commissioning and monitoring software

Elevator Connect PC Tool – CommissioningThe Connect PC Tool configures, optimizes and monitors drive/system control and performance |

Sản phẩm tương tự

Servo Drives

High Performance AC Drives

Specialist Drives

High Performance AC Drives

General Purpose AC Drives

DC Drives

CONTROL TECHNIQUES

High Performance AC Drives