DFS60S-S4OM01024

Safety encoders

DFS60S Pro

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

SKU: DFS60S-S4OM01024

Danh mục: Incremental encoders

Thẻ: 1089266, DFS60S-S4OM01024, Đại lý CẢM BIẾN SICK, đại lý phân phối cảm biến Sick, Sick Bà Rịa Vũng Tàu, Sick hcm, Sick sensor, Sick Tphcm, Sick VIỆT NAM, Sick Vietnam, Sick Vietnam Distributor, Sick Vũng Tàu

-

Safety-related parameters

Safety integrity level SIL2 (IEC 61508), SILCL2 (IEC 62061) 1) Performance level PL d (EN ISO 13849) 1) Category 3 (EN ISO 13849) PFHD: Probability of dangerous failure per hour 1.7 x 10-8 2) TM (mission time) 20 years (EN ISO 13849) Safety-related measuring step 0.09°, Quadrature analysis Safety-related accuracy ± 0.09° - 1) For more detailed information on the exact configuration of your machine/unit, please consult your relevant SICK branch office.

- 2) The values displayed apply to a diagnostic degree of coverage of 99%, which must be achieved by the external drive system and 95 °C operating temperature.

-

Performance

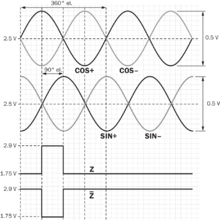

Sine/cosine periods per revolution 1,024 Measuring step 0.3 ″, with interpolation of the sine/cosine signals with e.g. 12 bit 1) Integral non-linearity Typ. ± 45 ″ (without mechanical tension of the stator coupling) Differential non-linearity ± 7 ″ - 1) Not safety-related.

-

Interfaces

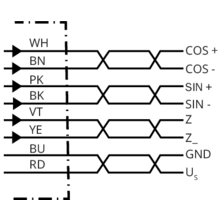

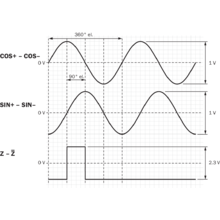

Communication interface Incremental Communication Interface detail Sin/Cos 1) Initialization time 50 ms 2) Output frequency ≤ 153.6 kHz Power consumption ≤ 0.7 W (without load) Load resistance ≥ 120 Ω - 1) 1.0 VSS (differential).

- 2) Valid signals can be read once this time has elapsed.

-

Electrical data

Connection type Cable, 8-wire, universal, 5 m 1) Supply voltage 4.5 … 32 V Reference signal, number 1 Reference signal, position 90°, electronically, gated with Sinus and Cosinus Reverse polarity protection ✔ Protection class III (according to DIN EN 61140) Short-circuit protection of the outputs ✔ 2) - 1) The universal cable connection is positioned so that it can be laid in a radial or axial direction without any kinks. UL approval not available.

- 2) Short-circuit to another channel or GND permitted for max. 30 s. In the case of US ≤ 12 V additional short-circuit to US permitted for max. 30 s.

-

Mechanical data

Mechanical design Solid shaft, face mount flange Shaft diameter 10 mm

With faceShaft length 19 mm Weight Approx. 0.3 kg 1) Shaft material Stainless steel Flange material Aluminum Housing material Aluminum die cast Start up torque ≤ 0.5 Ncm (+20 °C) Operating torque ≤ 0.3 Ncm (+20 °C) Permissible shaft loading 80 N (radial)

40 N (axial)

Operating speed ≤ 9,000 min⁻¹ 2) Moment of inertia of the rotor 8 gcm² Bearing lifetime 3.6 x 109 revolutions 3) Angular acceleration ≤ 500,000 rad/s² - 1) Based on encoder with male connector.

- 2) Allow for self-heating of approx. 3.0 K per 1,000 rpm regarding the permissible operating temperature.

- 3) On maximum operating speed and temperature.

-

Ambient data

EMC According to EN 61000-6-2, EN 61000-6-3 and IEC 61326-3-1 Enclosure rating IP65 (IEC 60529) 1) Permissible relative humidity 90 % (Condensation not permitted) Operating temperature range –30 °C … +85 °C 2) Storage temperature range –30 °C … +85 °C, without package Resistance to shocks 100 g, 6 ms (EN 60068-2-27) 3) Resistance to vibration 30 g, 10 Hz … 1,000 Hz (EN 60068-2-6) - 1) With male connector and mating connector fitted minimum IP65.

- 2) Allow for self-heating of approx. 3.0 K per 1,000 rpm regarding the permissible operating temperature.

- 3) Checked to operation with vector length monitoring.

-

Classifications

eCl@ss 5.0 27270501 eCl@ss 5.1.4 27270501 eCl@ss 6.0 27270590 eCl@ss 6.2 27270590 eCl@ss 7.0 27270501 eCl@ss 8.0 27270501 eCl@ss 8.1 27270501 eCl@ss 9.0 27270501 eCl@ss 10.0 27270501 eCl@ss 11.0 27270501 eCl@ss 12.0 27270501 ETIM 5.0 EC001486 ETIM 6.0 EC001486 ETIM 7.0 EC001486 ETIM 8.0 EC001486 UNSPSC 16.0901 41112113